MKsafety® understands that in high temperature workplaces, due to the influence of high temperature, it will have adverse effects on the production operation, physical health of the operators, and the use and storage of equipment materials and substances. In addition, it may also induce fires and explosions. High temperature workplace refers to the comprehensive temperature should comply with GBZ/T229.3-2010 workplace occupation.

There are three types of worksites that are exposed to high temperature and strong radiation, worksites with high temperature and high humidity, and outdoor worksites in summer. When the high-temperature working environment is very harsh, avoid heatstroke in summer every year, use water curtain air conditioners, perform local cooling in high-temperature workshops, and configure personal protective equipment.

1. Strengthen the education and training of personnel, understand the GB/T4200-2008 classification standards for high-temperature operations, establish and improve occupational hazard management institutions, and allocate personnel and instruments to carry out daily monitoring.

2. When performing high temperature monitoring, if there is no productive heat source in the workplace, select 3 measuring points and take the average value; if there is a productive heat source, select 3 to 5 measuring points and take the average value. If the work site is isolated as a different heat source environment or a ventilated environment, 2 measuring points are set in each area and the average value is taken.

3. For those who are engaged in high temperature operations all year round, choose to measure in the hottest month of summer; for irregular exposure to high temperature operations, choose to measure in the hottest month during the construction period. When the heat source is stable, test 3 times a day, after the start of the work shift and half an hour before the end Measure 1 time separately, 1 time in the middle of the work shift, and take the average value.

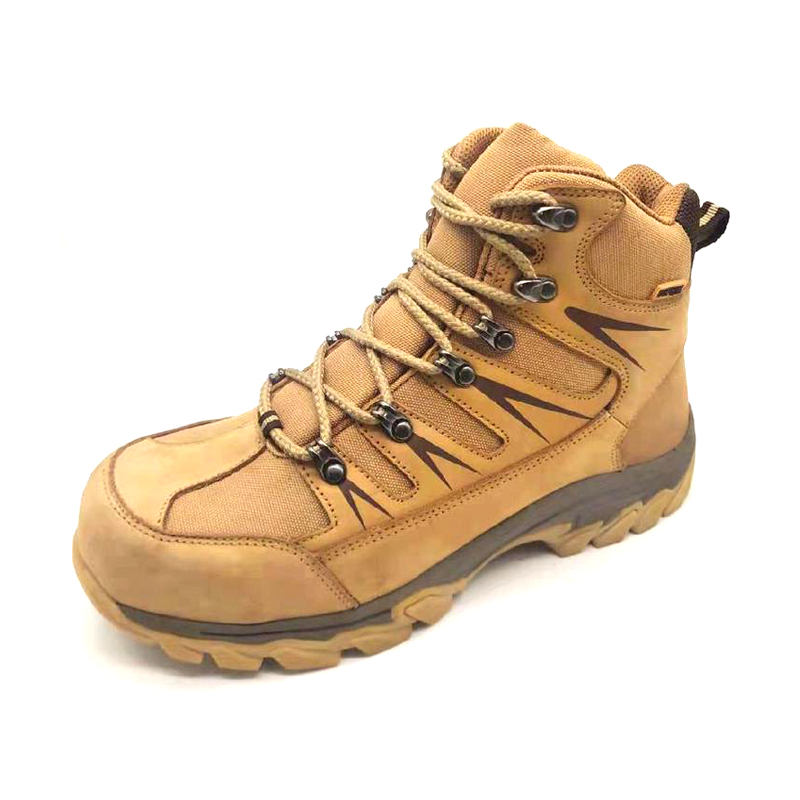

4. In the metallurgical industry, the meteorological characteristics of production places such as ironmaking, forging, heat treatment, glass, furnace workshops and thermal power plant boiler rooms are high temperature, high heat radiation intensity, and relatively low temperature, forming a dry heat environment . Personal protective equipment such as heat-insulating clothing and heat-insulating hoods must be worn for work, and conditions permitting can be used with cooling vests to improve comfort.

5. Open-pit coal mines should try their best to use mechanized operations to reduce the effects of high temperature and radiation; rationally adjust the operating time to avoid the strongest hours of sunlight, and provide employees with cooling vests.

6. Open-air operations such as farmland labor, construction, and transportation in summer are not only affected by the sun’s radiation, but also by the heat radiation from the surrounding objects on the heated ground. MKsafety® recommends that when the high temperature season comes, workers should be prepared with heatstroke prevention and cooling supplies and materials for avoiding high temperature operations; when working in high temperature seasons, the working hours of frontline employees should be shortened accordingly.

7. Strengthen the sprinkling of roads and stopes on site to reduce dust to achieve the effect of lowering the temperature; in rainy season, strengthen the drainage and keep the workplace humidity suitable.

8. Set up warning signs in high-temperature and high-humidity locations, and require ventilation as much as possible in high-temperature working locations.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.