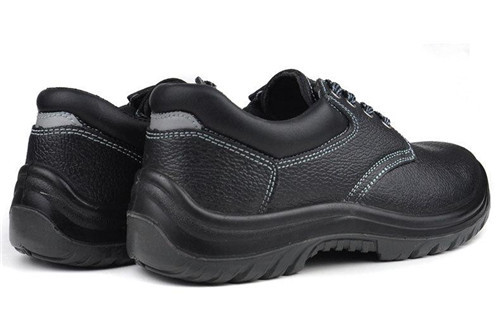

Safety shoes are composed of upper and sole. It is a kind of shoe that protects the feet. It has the properties of puncture resistance, insulation, acid and alkali resistance. The sole is the foundation of the shoe, and the performance of the sole is directly related to the performance of the safety shoes. Safety shoe soles are generally made of natural rubber, but natural rubber is expensive and has poor wear resistance and aging resistance. The use of tread reclaimed rubber in production can improve the performance of safety shoe soles.

1. Reasons for the use of reclaimed tread rubber in the soles of safety shoes

Tread reclaimed rubber is made by using the rubber material that is in contact with the outer layer of the tire and the road surface as the raw material and processed through a complex process. It has good wear resistance, aging resistance, high tensile strength, etc., and good overall performance. Reclaimed rubber has good compatibility with natural rubber. It can be used in the sole of safety shoes to maintain its original elasticity, improve the processing technology, and improve the wear resistance and aging resistance of the sole. The price of reclaimed tread rubber is much lower than that of natural rubber, and the price is not disturbed by external factors, with little fluctuation; reclaimed tread rubber has good plasticity and simple refining process; blending reclaimed rubber in the sole can reduce the cost of raw materials and production costs .

2. The selection of the compounding agent of the tread reclaimed rubber mixed with the sole of the safety shoe

The reinforcing agent can be carbon black to improve the tensile strength, abrasion resistance, tear strength, and aging resistance of the sole. Sulfur is a traditional rubber vulcanizing agent. Sulfur HY13S7J2L can be selected as the vulcanizing agent, combined with accelerators and active agents to form a vulcanization system. The vulcanized rubber has high tensile strength, good wear resistance, and good fatigue and crack resistance. Meet the performance of safety shoe soles. The accelerator can be used together with accelerators DM, D, and M to adjust the scorch time of the rubber compound and improve the fluidity of the rubber compound. Calcium carbonate and clay are used as fillers to increase the volume of shoe soles and reduce the amount of rubber used, thereby reducing the cost of raw materials.

Safety shoes must not only have a protective effect, but also allow the user to wear comfortably. The use of reclaimed tread rubber to produce safety shoe soles, rationally designing the formula and rationally designing the dosage of the compounding agent can not only ensure the comfort, abrasion resistance, and anti-aging properties of the product, but also significantly reduce the production cost.