Safety labor protection shoes are the most basic auxiliary safety products in production. The labor protection products industry is uneven, and customers often struggle to distinguish the quality of protective products. Today, Puqibian specializes in safety shoes and labor protection for foot protection. The main classification of shoes, usage requirements and usage environment, and testing requirements are explained in detail. There are many types of safety shoes. To enhance your understanding, Puqibian lists for you the 8 major categories of safety shoes among commonly used foot protection products. It is not a particularly strict academic product classification.

Main types of safety shoes:

1.Insulated safety shoes

The function of insulating shoes is to minimize the risk of electric shock. Because the current flows into the ground through the human body through the contact point when getting an electric shock, so not only insulating gloves but also insulating shoes must be worn when performing electrical work. According to the withstand voltage range, there are 25kV, 6kV and 14V insulated safety shoes, etc. when used, they must be selected according to the scope of work. Insulated shoes should be inspected and maintained regularly. If they are damp or severely worn, they will not be able to protect you. What we often use above are 6KV electrically insulated safety shoes. 6KV is the factory testing voltage, not the working voltage.

When using it, please note:

- Electrically insulated leather shoes with a withstand voltage of less than 15kV are suitable for operating environments with power frequency voltages of less than 1kV;

- When wearing electrically insulating leather shoes, the working environment should be able to keep the uppers dry;

- Contact with sharp objects, high temperatures and corrosive substances should be avoided to prevent the shoes from being damaged and affecting the electrical performance;

- The results of each preventive inspection are valid The term shall not exceed 6 months. There are also high-voltage insulated shoes on the market. Sometimes we need to use 35kv insulated boots when working in high-voltage environments.

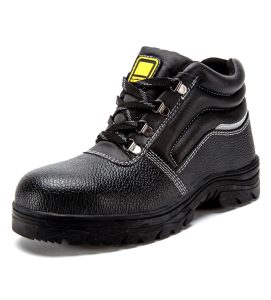

2.Anti-smash safety shoes

Anti-smash safety shoes, also known as toe-protecting safety shoes, are mainly designed to prevent objects from damaging the feet and toes. For example, when carrying heavy objects or loading and unloading materials, rolling drums, heavy pipes hit your feet, or you accidentally kick up sharp metal plates, etc. The front toe cap of the shoe is lined with a metal material with good impact resistance, high strength and light weight. Its strength and impact resistance must be tested and can only be used if it meets the prescribed standards. Pay attention to choosing safety shoes of different strengths according to the severity of the work.

3.Anti-static shoes or conductive shoes

Anti-static shoes are suitable for preventing accidents caused by static electricity on the human body and preventing accidental electric shock to the human body caused by 220V power frequency capacitive equipment. Conductive shoes are used in places where fires or explosions are more likely to occur and are more sensitive to human body static electricity. Some of these shoes are safety shoes and rubber shoes with anti-static or conductive soles. The entire shoe does not use metal to reduce the possibility of friction and fire. Shoes must be tested for resistance from the beginning of use. This is followed by periodic testing to ensure that the maximum resistance value of the shoe does not exceed the allowable value.

4.Steel-making shoes and shoe covers

This type of shoes, also called caster shoes, mainly prevents burns and punctures on the feet. This kind of shoes should be resistant to pressure and not easy to burn. The uppers are made of oil-impregnated cowhide and canvas-lined leather, and the soles are made of tire-lined cowhide. In order to prevent burns caused by molten metal splashing, they are all designed to be high-waisted and easy to take off. You can also use shoe covers to cover shoe openings and trouser legs. Shoe covers are mostly made of canvas, asbestos, or aluminum film.

5.Cold-proof shoes, also known as winter safety shoes

Cold-proof safety shoes are special types of safety shoes designed to protect the feet of workers in low temperature or cold working environments. They are warm, waterproof, non-slip and wear-resistant, and can effectively provide sufficient protection and comfort.

When working in a cold environment, your feet are easily attacked by cold air, leading to problems such as frostbite and chilblains. Cold-proof safety shoes solve this problem by using thermal materials and insulation technology. These materials can effectively block the entry of cold air and keep your feet warm. Some common thermal insulation materials include wool, flannel, special thermal fibers, etc. In addition, there are some special thermal insulation technologies, such as thermal insulation layers, nano-insulation materials, etc., which can provide better thermal insulation effects.

Cold-proof safety shoes are also waterproof, which can prevent moisture from penetrating into the shoes. This is especially important for those who need to work in rain or snow. The waterproof function is usually achieved by using special waterproof materials and processes, such as waterproof coatings, waterproof membranes, etc. These waterproof materials can effectively block moisture penetration and keep feet dry.

This type of safety shoes is generally used for outdoor work and is suitable for use in severe cold and low-temperature environments. There are cotton shoes, fur boots and felt boots, etc., with good thermal insulation properties. Generally, safety shoes can be made into safety shoes with cotton added in winter.

6.Anti-puncture safety shoes

Puncture-resistant labor protection shoes are installed with a 0.05mm degreased stainless steel midsole plate on the sole to prevent sharp and hard objects such as nails from piercing the sole of the shoe and injuring the soles of employees. Its puncture resistance is greater than 1100 Newtons , in line with the national standard GB21148-2007, for super strength. Mainly suitable for mining, machinery, construction, metallurgy, logging, transportation and other industries. Our anti-puncture safety shoes are usually equipped with anti-puncture and anti-smash functions at the same time, but cannot be paired with insulation functions.

7.Acid and alkali resistant safety shoes

Acid and alkali resistant safety shoes are a type of footwear protective equipment specially designed for use in acid and alkali environments. They have undergone strict protective testing and quality control to ensure that they have a good protective effect in acid and alkali environments and effectively prevent acid and alkali. Accidental injuries such as splashing.

Common acid and alkali resistant safety shoe materials include rubber, polyurethane, polypropylene, etc. Choose the appropriate material according to the working environment and chemical properties.

Acid and alkali resistant safety shoes have different protection levels. For example, choose the appropriate protection level according to the acid and alkali concentration and temperature to ensure that they can adapt to the needs of the working environment.

Acid and alkali resistant safety shoes are suitable for electroplaters, pickling workers, electrolyzers, liquid dispensers, chemical operators, etc. Acid and alkali resistant labor protection shoes can only be used in acid and alkali workplaces with low concentrations; contact with high temperatures should be avoided. Sharp objects damage the upper or sole leakage; after wearing, rinse the acid and alkali liquid on the shoes with clean water, and then dry them to avoid direct sunlight or drying

8.High temperature resistant safety shoes (also known as heat-insulating shoes)

There are special high-temperature working environments in the production process. At this time, employees need a pair of safety shoes with good heat resistance, such as metallurgy, boilers, electric welding, etc. High-temperature resistant safety shoes are usually made of rubber soles in the protective equipment market, and the requirement is 300 degrees Celsius, some products even reach 500 degrees Celsius. Of course, there are higher temperatures. For those that have basically transcended conventional safety shoes, you need to note that rubber-soled safety shoes are a little heavier, but their heat resistance is much stronger than that of PU or PVC and other materials. Because it is a rubber base leather, it is usually made using glue and hand and machine stitching.

The main testing indicators for safety labor protection shoes are roughly listed below:

Impact resistance of Baotou

Use a steel impact hammer with a specified weight to carry out an impact test. When the Baotou is impacted, the gap height under the Baotou should be less than the specified value, and there should not be any penetrating cracks in the Baotou in the direction of the test axis. It is worth noting that national standards have different regulations on the weight, specifications, impact height of impact hammers and the structure of the testing machine, which should be distinguished during actual testing.

Puncture resistance

The testing machine is equipped with a pressure plate, and the pressure plate is equipped with a test nail. The test nail is a head with a truncated tip. The hardness of the nail head should be greater than 60HRC. Place the shoe sole sample on the chassis of the testing machine in such a position that the test nail can pierce through the outsole. The test nail pierces the sole at a speed of 10 mm/min ± 3 mm/min until it penetrates. Record the required the maximum force. Select 4 points on each sole for testing (at least 1 point of which is at the heel). The distance between each point is not less than 30 mm and the distance from the edge of the insole is greater than 10 mm. There is a bottom with anti-slip blocks, which should be pierced between the blocks. Two of the four points should be tested within a distance of 10-15 mm from the edge line where the base corrugation is located. If humidity will affect the results, the soles should be immersed in deionized water at 20℃±2℃ for 16±1h before testing.

Electrical properties of conductive shoes and anti-static shoes

After the shoe sample is conditioned in a dry and wet atmosphere, clean steel balls are filled into the shoe and placed on the metal probe device. Use the specified resistance testing instrument to measure the first two probes and the third probe. resistance between. Under normal circumstances, conductive shoes require resistance not greater than 100K ohms; anti-static shoes require resistance between 100K ohms and 100M ohms.

Thermal insulation performance

Use the finished shoe as the sample, install the thermocouple at the center of the insole connection area, and fill the steel ball into the shoe. Adjust the temperature of the sand bath to 150°C ± 5°C. Place the shoe sample on it so that the sand contacts the outer sole of the shoe. Use a temperature testing device connected to a thermocouple to measure the temperature of the inner sole and the corresponding time. , giving the temperature increase curve. Calculate the temperature increase 30 minutes after the specimen is placed on the sand bath. Generally, insulated shoes require that the temperature increase on the inner sole surface is less than 22°C.

Energy absorption performance of the heel part

The testing instrument has a maximum compressive load of 6000N and is equipped with a device for recording load/deformation characteristics. Place the heeled shoe sample on a steel plate and place the test punch inside the center of the heel part against the insole. Apply load at a speed of 10 mm/min ± 3 mm/min. Plot the load/compression curve and calculate the absorbed energy E expressed in joules.

Requirements for anti-slip outsole

Anti-slip performance is one of the most important testing indicators of safety shoes. In the working environment, the ground may have various slippery conditions, such as water, oil, etc. The anti-slip performance of safety shoes is directly related to whether workers can stand and walk stably. The test methods for anti-skid performance include the determination of static friction coefficient and dynamic friction coefficient. Normally, the anti-slip performance of safety shoes should meet the requirements of the corresponding national standards.