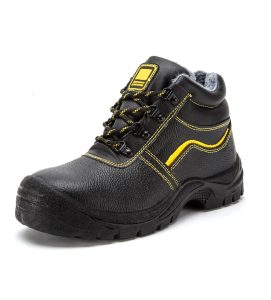

Anti-slip safety shoes are a type of footwear specifically designed for use in the workplace, with the primary purpose of providing additional protection and anti-slip features to reduce the risk of injury to workers on slippery or slippery surfaces.

Such shoes are usually made of wear-resistant materials and have special sole designs that provide better grip and anti-slip properties.

Workplaces often present a variety of potential slip and fall hazards, such as wet floors, grease-contaminated surfaces or uneven floors. These dangerous situations can cause workers to slip, fall or even be seriously injured. Therefore, it is very important to wear non-slip safety shoes, which can effectively reduce the occurrence of these accidents.

One of the main features of non-slip safety shoes is their sole design.

The soles are usually made of rubber, polyurethane or other wear-resistant materials that have good anti-slip properties. In addition, there will be special patterns and groove designs on the soles to increase friction with the ground. These designs provide better grip, making workers more stable on slippery or slippery surfaces.

Another important feature is the wear resistance of non-slip safety shoes.

Since the working environment is often harsh, shoes can be easily damaged by friction and wear. Therefore, anti-slip safety shoes are usually made of wear-resistant materials to increase their service life. These materials resist wear and damage from daily use, extending the life of your shoes.

Non-slip safety shoes are often graded based on their anti-slip properties.

These grades are determined based on sole material, pattern design, and relevant testing standards.

Here are some common slip resistance grades and their associated requirements:

SRC level:

This is the highest level of anti-slip shoes. The soles must be able to provide a high degree of slip resistance when attached to steep steel floors and remain stable on grease-coated ceramic floors. The sole material of this level is usually made of rubber or polyurethane, and has a special pattern design to provide better anti-slip effect.

SRA level:

This level requires the sole to have good anti-slip properties when adhering to steep steel surfaces. Compared to the SRC grade, the SRA grade sole has slightly less slip resistance on grease-coated ceramic floors. However, it still provides adequate anti-slip protection.

SRB level:

SRB level soles can provide good anti-skid performance on grease-coated ceramic floors, but have relatively poor anti-skid performance on steel floors. This level of sole is typically suitable for work environments where oils and grease are handled.

In addition to these grades, there are other anti-slip grades, such as SRC+, SRA+, etc., which usually indicate that the soles have better anti-skid performance in special working environments.

When choosing anti-skid safety shoes, in addition to considering their anti-skid level, you should also pay attention to the following points:

Sole material:

Rubber and polyurethane are common sole materials, and they have good anti-slip properties. In addition, some soles are added with special anti-slip materials, such as silicon carbide and natural minerals, to provide better anti-slip effects.

Pattern design:

The pattern design of the sole is also a key factor affecting the anti-skid performance. Deep and dense patterns can increase the friction between the sole and the ground, providing better anti-slip effect.

Comfort:

In addition to anti-slip performance, comfort is also a factor to consider when choosing anti-slip safety shoes. The fit, breathability, and cushioning of shoes all impact workers’ work experience.

To sum up, anti-slip safety shoes are important equipment to protect workers’ safety.