Since the birth of safety shoes, it has taken on the important task of protecting the feet of workers from external injuries. With the upgrading and iteration of the production process of safety shoes, the functional subdivision of safety shoes is becoming more and more clear, and there are more and more types. However, no matter the update iteration, most of the safety shoes have the most basic anti-skid performance.

Some staff often encounter stagnant water and oil pollution in their working environment, which is prone to slip and fall injuries and affects work efficiency. When evaluating the need for anti-slip, it is necessary to consider the ground, pollutants, footwear, pedestrian personal factors, cleanliness and the environment. In order to reduce the occurrence of slipping injuries, in addition to taking administrative measures, it is necessary to wear non-slip safety shoes to reduce the occurrence of slipping injuries. Anti-slip safety soles are particular, and the texture of the material is the key.

Non slip safety shoes are a kind of safety shoes. The anti-skid and wear resistance of safety shoes are mainly improved through the selection of materials used in the out sole and the design of the shading, so as to achieve the purpose of anti-slip.

The sole material of different safety shoes has different characteristics. Understand the material of the sole and choose the appropriate safety shoes in order to better provide safety protection for users.

The sole material of safety shoes is generally divided into rubber (RB), polyurethane sole (PU), MD sole, TPR sole, EVA sole, etc. according to the material. Different materials have different anti-skid properties.

From the material point of view, the anti-slip performance is better than natural rubber. Sometimes whether the shoes are anti-slip can not only depend on the material of the sole, but also the design and technology of the sole. So even if it is a shoe with the best anti-slip effect, it may slip.

Different sole patterns, widths, directions, depths, etc. will affect the anti-slip performance. Most people think that the more patterns on the sole, the more anti-slip, but this is not certain. It’s not that the more textures, the more anti-skid, there is a certain technology in it. Under the same road conditions, the anti-slip performance of the broken line pattern is better than that of the horizontal and vertical patterns;

There is also a spike-like pattern designed to grasp the ground through the protruding particle shape, which has a good grip. The larger the pattern width of the sole, the larger the coefficient of friction and the better the anti-skid performance. When the pattern direction is 0° and 45°, the friction coefficient between the soles is larger, and the anti-skid performance is also better.

There are some general guidelines to consider when choosing the right anti-slip feature.

Out sole:

Soft Rubber Compound Provides Maximum Slip Resistance For Environments Contaminated With Oil And Grease. Remember that small changes in compound can lead to large changes in overall slip resistance.

Tread:

Look for out soles that shed oil and grease so the out sole can more fully contact the work surface, and ones with split solid lugs specifically designed to clear away debris. Treads should allow the maximum amount of material to grip the floor. Softer soles and tighter treads are better suited to fluid contaminants in indoor environments. Wider-spaced treads are generally better suited for handling solid contaminants in outdoor areas. Avoid clogging the tread. If the footwear requires frequent cleaning, it may require a wider or deeper tread pattern. Watch out for worn or flat soles over time.

Insoles:

Insoles do not directly provide slip resistance, but they should provide additional cushioning and impact padding for employees who stand for long periods of time or work on hard surfaces.

Upper:

Uppers can be made from a variety of materials, including various leathers, suede, mesh, and combinations of these materials. Like the insole, the upper does not directly determine slip resistance, but plays a key role in fit and comfort.

Mid sole:

Mid sole technology is not directly related to slip resistance, but is very important to the overall structural integrity of the footwear and the comfort of the employee throughout the day.

Durability:

Employers should prioritize highly durable footwear that provides maximum slip resistance for the longest period of time so employees can work with confidence.

MK Safety Shoes is a safety shoes supplier with 15 years of experience in manufacturing safety shoes China. Unique understanding of the production and design of Anti-static safety shoes. Not only can we design comfortable and stylish shoes, but we can also make safety shoes multifunctional.

Next I will introduce 6 of our company’s leather safety shoes

MK A2009

The outer skin of this waterproof safety shoes is made of high-quality second-layer cowhide, making the shoes less likely to wrinkle. Colleagues who increased the performance of the shoe also took into consideration the softness and breathability of the shoe. Comfortable colleagues also take into account the beauty of the shoes, ensuring the upright shape of the shoes. In order to increase the wear resistance of the shoes, a wear-resistant rubber outsole is specially used, which has strong deep grip and strong anti-slip performance. Built-in anti-smash steel toe midsole, using lightweight puncture-proof Kevlar midsole, which can well protect our toes and soles. The shoe collar and shoelaces are made of elastic elastic bands, which are very convenient to put on and take off, and are durable and stretch-resistant. The design of the elevated upper is ergonomic and protects the ankle joint and Achilles tendon from friction and compression of the foot.

Our shoes look and perform great. You can choose them based on your work environment and preferences.

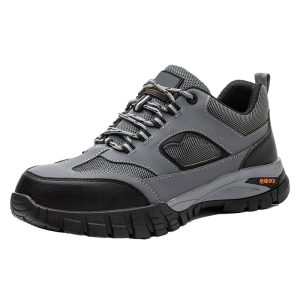

MK1038

The upper of this lightweight safety shoes uses a combination of pigskin and breathable mesh, which makes the shoes very breathable and comfortable to wear, and gives you a lasting refreshing feeling. The sole adopts a lightweight rubber-plastic outsole, which is comfortable, soft and shock-absorbing, and will not be tired for long-term walking. The pixel outsole is also wear-resistant, tear-resistant and non-opening glue, which increases the durability of the shoes. The sole adopts Kevlar bulletproof fabric midsole to cover the entire sole, which is softer, lighter and more comfortable. The toe cap is made of up-to-standard anti-smashing steel toe, effectively avoiding toe injury. The scorpion is made of lightweight material, which is easy to put on and take off without getting tired. Adding reflective material to the heel is safer to walk at night.

MK2048

This is a non slip safety shoes with a cowhide upper. It has a fashionable Chelsea style, a lot of functions, and a very good quality. It has: anti-slip, anti-smash, anti-puncture, wear-resisting, oil-proof and many other functions. The sole is made of PU integrated injection, and the inner lining of the shoe is made of breathable and comfortable material. It is not stuffy and very light. And the price is cheap, it is a very cost-effective safety shoe, which is why I recommend it to everyone here. This pair of shoes sells very well, if you want to use better materials, we can also customize it for you. These shoes can also be made into very high-end shoes.

If your working environment is watery or oily, you can choose these shoes, which are not only lightweight but also functional and very fashionable.

MK 1042

A pair of sport safety shoes made for comfort. The national standard plastic sprayed steel toe cap can effectively protect the safety of the organization, and the plastic sprayed anti-piercing midsole protects the soles of the feet from sharp objects. The sole adopts polyurethane injection process, no glue, constant bottom, oil resistance and non-slip.The inner lining of the mesh has good air permeability, and the shoelace is designed with a zipper, no longer need to tie the shoelace, no need to worry about the loosening of the shoelace, it can be tightened instantly with one push and one pull.

MK 0333

This is a leather work boots suitable for various industries. It is a very common safety shoe in the traditional sense. This shoe uses a cowhide upper, and the sole uses a PU injection integrated sole. Very wear-resistant and non-slip. His upper is also a little waterproof and oil-proof. As for the line on the surface of the shoe, you can change the overall color according to your preference. The shoe head uses a steel head, and the midsole uses a steel plate. Excellent anti-smash and anti-puncture performance. Some light-emitting strip materials are also used behind the shoes, which can make you more eye-catching under the light. This shoe is our best-selling shoe. It is used in a relatively large amount, and the quality is better, and there are few problems.

If you work in industry and heavy industry, I recommend this shoe. Simple and comfortable, safe and reliable.

MK 0583

This is a military safety shoe in camouflage colors. The colorful appearance is very suitable for all kinds of environments. The biggest feature of this pair of shoes is the camouflage color, stain-resistant and durable, stylish and simple. There is a wide range of buyers for this pair of shoes. Many buyers will choose this pair of shoes for his workers. His upper also uses breathable mesh, and the sole uses a high-quality rubber sole. He used a steel toe for his toe protection, and a steel plate in the midsole. Very strong and durable. The price of this pair of shoes is relatively low and is loved by many people.

The above are the top ten best-selling safety shoes of our company. For how to choose safety shoes, we still need to decide according to our working environment. Nowadays, safety shoes are more and more similar to ordinary sports shoes, so I think safety shoes will be as popular as ordinary sports shoes and sell well.